Our Services

Stag supply a wide range of CNC turned parts, including plated, heat treated and annealed alongside of many other surface requirements to a broad spectrum of customers within high specification engineering sectors

Capabilities and size range

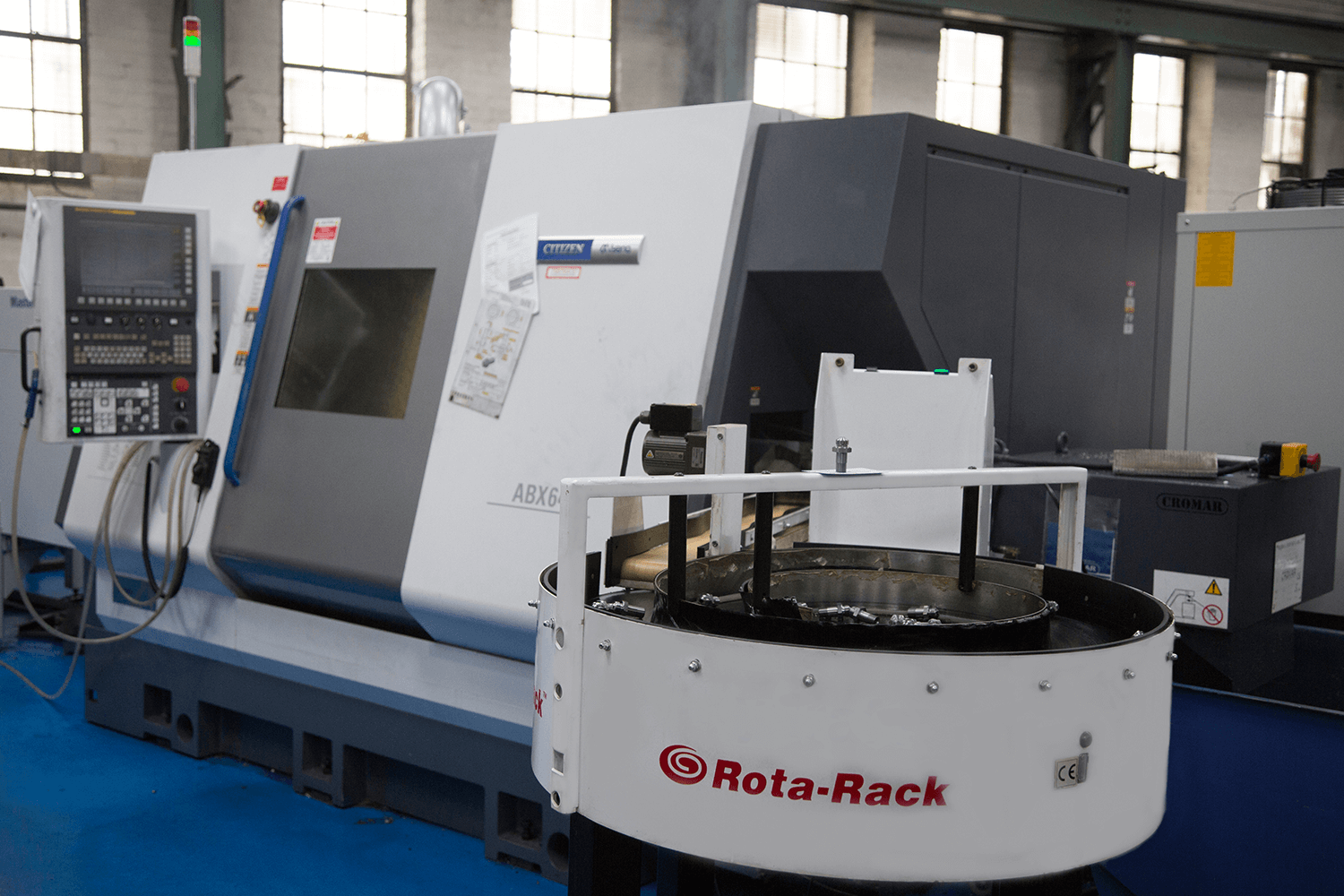

As a quality precision engineering company with a wide range of capabilities, Stag manufacture high quality turned components from 1 to 64mm diameter from a recently refurbished 25,000 square foot factory. With our high precision mill turn lathes and swiss sliding head machinery, our engineers can produce simple or complex precision components within this size bracket, with the most complex and demanding features the customer may have.

Our understanding

With a full understanding of typical components utilising tools such as APQP stag are able to work alongside customers in producing parts right first time. Any potential clash of tolerance / obvious design mistakes are ironed out.

During production Capability studies are carried out on critical features as are extra requirements such as roundness which Stag believe to be one of the most critical features on a cylindrical machined part.

Tolerances regularly maintained on turned diameters and lengths are within 10 microns whereby if features require higher specification such as 5 microns the part would be ground in house on our CNC cylindrical grinding section or manual centreless section.

Certification and Industry

Certification to ISO 9001 is maintained along with the utilisation of many aspects of IATF 16949:2016 such as PPAP to level 3.

Full traceability of material and sub contract processes are maintained through a dedicated ERP system.

Stag supply a wide range of CNC turned parts, including plated, heat treated and annealed alongside of many other surface requirements to a broad spectrum of customers within high specification engineering sectors. Our clients come from sectors including;

Agriculture, Earth Moving, Automotive, Electronic and Hydraulic Industries including major OE Companies and many first-Tier suppliers with a global presence.

Certification and Industry

Certification to ISO 9001 is maintained along with the utilisation of many aspects of IATF 16949:2016 such as PPAP to level 3.

Full traceability of material and sub contract processes are maintained through a dedicated ERP system.

Stag supply a wide range of CNC turned parts, including plated, heat treated and annealed alongside of many other surface requirements to a broad spectrum of customers within high specification engineering sectors. Our clients come from sectors including;

Agriculture, Earth Moving, Automotive, Electronic and Hydraulic Industries including major OE Companies and many first-Tier suppliers with a global presence.

Machine Types

Our plant include the following types of machine:

CNC Machine

CNC (Computer Numerically Controlled) Machines are programmed and controlled by computer so can offer very short set up times and the flexibility to run batches from one offs to several thousand

Fixed Head Lathe

A type of lathe where the headstock remains in a fixed position and the tooling moves backwards and forwards to cut in the desired position.

Multi-spindle Lathe

Multi-spindle machines have up to eight spindles. Each spindle moves from tool to tool in turn. Because up to eight operations are carried out simultaneously extremely fast cycle times can be achieved.

Sliding Head Lathe

A type of lathe where the headstock both rotates and moves forwards and backwards. This means that machining is carried out at the support position to give optimum cutting conditions. Such machines are particularly suited to long slender parts and large batches of small components.

Machine Operations

Boring

Drilling

Milling

Tapping

Threading

Turning

Contact

Stourbridge Turning & Grinding

Rufford Road, Stourbridge

West Midlands, DY9 7NE

United Kingdom

tel +44 (0)1384-443050